China Factory Large Diameter Custom Size Steel Split Sprocket Supplier

Product Description

Our extensive range of large diameter custom size steel split sprockets is designed to meet the highest industry standards, ensuring durability, precision, and performance. Manufactured to DIN standards, our industrial sprockets offer various options in bore types, colors, and treatments to suit different applications.

| DIN Standard Industrial Sprocket | |

| Bore | Finished bore, Processing bore, Taper bore |

| Color | Natural steel or black |

| Standard | ANSI, DIN, ISO |

| Type | Simplex, Duplex, Triplex |

| Surface Treatment | Black oxide, Zinc plated |

| Heat Treatment | High Frequency Quenching |

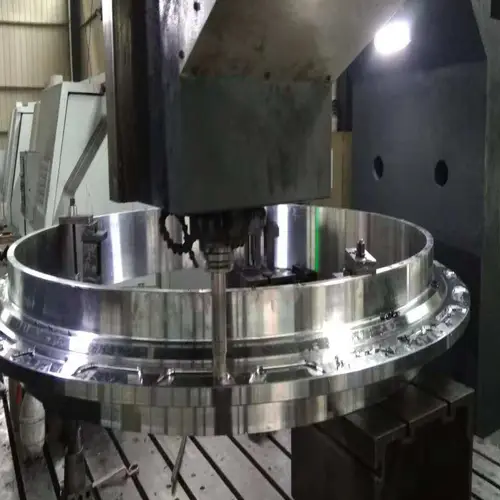

Detailed Photos

1. Chain Used

HRSY sprockets are engineered with precise tooth profiles and dimensional accuracy to maximize the performance of the chain used.

2. Number of Teeth

HRSY sprockets come in various configurations with both small and large numbers of teeth to adapt to different usage conditions.

| Single Pitch Sprocket | Double Pitch Sprocket | ||||

|

*Chain matched: 35(06C) / 06B Teeth: 9-120 *Chain matched: 40(08A) / 08B Teeth: 9-120 *Chain matched: 50(10A) / 10B Teeth: 9-120 *Chain matched: 60(12A) / 12B Teeth: 9-120 *Chain matched: 80(16A) / 16B Teeth: 9-120 *Chain matched: 100(20A) / 20B Teeth: 9-120 *Chain matched: 120(24A) / 24B Teeth: 9-120 *Chain matched: 140(28A) / 28B Teeth: 9-120 *Chain matched: 160(32A) / 32B Teeth: 9-120 *Chain matched: 200(40A) / 40B Teeth: 9-120 |

*P = 25.4mm Teeth: 7-100 *P = 31.8mm Teeth: 7-100 *P = 38.1mm Teeth: 7-100 *P = 50.8mm Teeth: 7-100 *P = 63.5mm Teeth: 7-100 |

3. Construction

Available in A type, B type, C type, and SD type configurations to cater to diverse mechanical needs.

4. Material

Our sprockets are manufactured from a variety of materials including Carbon Steel, Stainless Steel, Aluminum, Nylon, POM, Copper, Brass, 42CrMo, 40Cr, and A3.

5. Bore

Options available include Pilot bore, finished bore, taper bore, bearing hole, and specialized bores tailored to your specifications.

6. Treatment

Heat Treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching.

Surface Treatment: Zinc Plating, Chrome plating, Black oxide Treatment, Spray Paint, Mirror Finish, Sand-blasting.

Packaging & Shipping

Our packaging ensures the safety and integrity of the sprockets during transit. Reliable and prompt shipping services are provided to deliver your orders efficiently.

Other Product Businesses

EVER-POWER GROUP specializes in a broad range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We emphasize top-quality products, competitive prices, and exceptional customer service. Customization of drawings and samples is warmly welcomed to meet specific requirements.

FAQs

1. What types of bores are available for the sprockets?

We offer finished bores, processing bores, taper bores, and specialized bores to suit various applications.

2. What materials are your sprockets made from?

Our sprockets are manufactured from materials such as Carbon Steel, Stainless Steel, Aluminum, Nylon, POM, Copper, Brass, 42CrMo, 40Cr, and A3.

3. Do you offer custom sprocket designs?

Yes, we provide OEM services and can customize sprocket designs based on your drawings and specifications.

4. What surface treatments are available for your sprockets?

We offer various surface treatments including Zinc Plating, Chrome plating, Black oxide Treatment, Spray Paint, Mirror Finish, and Sand-blasting.

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.

Performance Characteristics of Large Sprocket

Durability

Large sprockets are designed to withstand extreme stress and heavy loads. The robust construction ensures long-lasting performance, minimizing the need for frequent replacements.

Efficiency

Large sprockets offer superior energy transfer efficiency, ensuring minimal power loss during operation. This leads to optimized performance in various mechanical systems.

Precision

Engineered with high precision, large sprockets ensure accurate synchronization of chain movements, which is critical for the smooth operation of machinery.

Adaptability

Large sprockets are available in various sizes and configurations, making them adaptable to different types of machinery and applications.

Types and Characteristics of Large Sprockets

Fixed Sprockets

Fixed sprockets are permanently attached to a shaft, providing a stable connection that ensures consistent performance in applications requiring steady power transmission.

Detachable Sprockets

Detachable sprockets are designed for easy removal and replacement, making maintenance and repair processes more convenient.

Split Sprockets

Split sprockets are engineered to be split into two or more parts, allowing for assembly and disassembly without dismantling the entire system.

Advantages of Large Sprockets Made of Different Materials

Steel Sprockets

Steel sprockets are known for their exceptional strength and durability, making them ideal for heavy-duty applications.

Aluminum Sprockets

Aluminum sprockets are lightweight and resistant to corrosion, which makes them suitable for applications where weight and environmental factors are crucial.

Plastic Sprockets

Plastic sprockets are cost-effective and provide good resistance to wear and tear, making them an excellent choice for less demanding applications.

Applications of Large Sprockets

Manufacturing and Industrial Machinery

Large sprockets play a vital role in manufacturing and industrial machinery, ensuring efficient power transmission and enhancing the productivity of conveyor systems and other mechanical processes.

Agricultural Machinery

In agricultural machinery, large sprockets are essential for the functioning of tractors, harvesters, and other equipment, facilitating smooth operation and efficient transfer of power.

Construction Equipment

Construction equipment such as cranes, excavators, and bulldozers rely on large sprockets for reliable power transmission, ensuring the effective performance of these heavy machines.

Marine Applications

Large sprockets are used in marine applications to drive various components, contributing to the overall efficiency and reliability of marine vessels.

Mining and Quarrying

In the mining and quarrying industry, large sprockets are crucial for the operation of conveyor belts, crushers, and other heavy machinery, enabling the smooth and efficient extraction of resources.

Future Development Trends and Opportunities of Large Sprocket Products

As technology advances, the development of large sprockets is expected to focus on enhancing material properties, improving manufacturing techniques, and increasing the precision of designs. Opportunities for innovation include the integration of smart technologies for real-time monitoring and maintenance, as well as the development of eco-friendly materials to reduce environmental impact.

Suggestions and Outlook: Choosing a Suitable Large Sprocket

Clear Requirements

Identify the specific requirements of your application, such as load capacity, speed, and environmental conditions.

Material Selection

Choose the appropriate material based on the operating environment and the mechanical demands of your application.

Design Optimization

Ensure that the sprocket design is optimized for maximum efficiency and longevity.

Suppliers and After-Sales Service

Select reliable suppliers who offer comprehensive after-sales support and services.

Cost-Effectiveness

Evaluate the cost-effectiveness of the sprockets, considering factors such as initial cost, maintenance, and lifecycle.

Quality Control

Implement stringent quality control measures to ensure that the sprockets meet the required standards and specifications.

Summary

Large sprockets are indispensable components in various industries, offering durability, efficiency, precision, and adaptability. Understanding the types, materials, and applications of large sprockets can help in making informed decisions. As the industry evolves, advancements in technology and materials will continue to drive innovation, presenting new opportunities for enhanced performance and sustainability. Selecting the right large sprocket involves careful consideration of requirements, material selection, design, and supplier support, ultimately leading to improved operational efficiency and cost-effectiveness.

Author: Dream